It was rated at 200 HP and it was originally used as the base motor in the Intrepid and Concorde, but it’s been the optional engine in the Stratus and Sebring since 2001 and it will be the standard engine in Chrysler’s new 300 sedan that’s coming out later this year.

So, while there are over a million and a half of these engines in service and they’re still being built today, the 2.7L has been tweaked and tuned along the way, so there are just enough differences to cause some problems if you’re not careful. There are two blocks and four heads along with two tensioners and two different cam sprockets plus a couple of other minor changes, so it’s easy for a rebuilder to make a mistake that will cost him some money. With that in mind, let’s take a look at the 2.7L engine and see what Chrysler has done to it since the beginning.

Blocks

There’s only been one block casting used for the 2.7L, but there are two versions of it with one small, but important, difference.

1998-00: The original block that was used in the LH cars in ’98 and ’99 had a 4663611 casting number. It was an aluminum casting with cast iron liners and four powdered metal main caps that were crossbolted to the block. The 2.7L was installed “north-south” in the LH cars with the front of the block facing the front of the car.

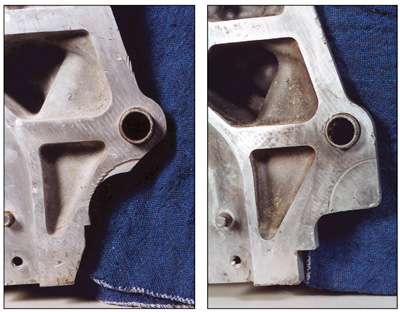

2001-’03: When the 2.7L engine was installed in the Stratus and Sebring cars in 2001, the block had to be modified to make it fit in the new “east-west,” transverse application, so the back corner of the bell housing on the passenger side was relieved to

provide enough clearance for the starter on the cars that came with manual transmissions. All the blocks were modified beginning in 2001, but the LH cars didn’t need the extra clearance for the starter, so you can still use the earlier block without this modification for the LH cars up through 2003. This is all pretty straightforward except that the casting number – 4663611 – is the same for both versions of the block, so rebuilders will have to look at each one to see if it’s relieved before using it for a Stratus or Sebring.

Cranks

There’s only been one crank used in the 2.7L motor, but it had a hole in the snout for a pin through 2002 and a slot for a key beginning in 2003. It’s a steel forging with no identification number on it, so rebuilders will have to learn to recognize it by sight.

Rods

Chrysler has used only one rod in the 2.7L. It’s a powdered-metal forging with a cracked cap. There’s no identification number on it, either.

Pistons

There’s really only been one piston used in this engine since ’98. There are a few subtle differences between the early ones and late ones because Chrysler switched suppliers from KSG to Mahle in 2001, but they’re virtually identical and completely interchangeable.

Heads

All of the 2.7L heads are DOHC, aluminum castings and they all look pretty similar, but that’s misleading because there are four different versions with two for the right side and two for the left side.

1998-’99 Right Side: The 4663979 head casting was used on the passenger side in ’98 and ’99. It had a threaded hole in the side of the head, up close to the front, for the screw-in cover that held the primary chain tensioner in place. There were a few of the early castings that had a raised bolt boss on the front of the head for a bracket that supported the wiring harness, but Chrysler switched to a clip that was bolted to the rocker cover soon after production began, so the bolt boss was deleted.

2000-’03 Right Side: The 4663979AB casting replaced the original right hand head beginning in 2000. There were two differences:

1. The chain tensioner was held in place with a flanged cover that was bolted to the head, so the big hole wasn’t threaded and there were two, small, threaded holes beside it for the cover.

2. There were two additional bolt bosses on the front corner, right above the hole for the chain tensioner, that were used for the power steering pump on the JR cars beginning in 2001.

1998-’99 Left Side: The left head used for the 1998-’99 LH cars was a 4663697 casting. It had two bolt bosses midway back on the side of the head, right below the rocker cover rail.

2000-’03 Left Side: The original driver’s side head was replaced by the 4663697AB in 2000. There were two more bolt bosses added closer to the front of the head, so there were four of them right below the rocker rail on these later heads.

Although the heads with the extra bolt bosses came out in 2000, it appears that extra bolt holes weren’t actually used until model year 2001 when the 2.7L engine was installed in the Sebring and Stratus and the alternator and power steering pump were bolted directly to the bolt bosses that were added to both heads.

Cams

This is a DOHC motor, so it has four cams, a right and left intake and a right and left exhaust. They’re all hollow cams with pressed-on lobes and they each have an identification mark etched on the barrel between the fourth and fifth lobes that’s coded by location.

Right hand intake: Both of the intake cams have an oblong pad with two bolt holes for the cam gear plus a sprocket for the short chain that drives the exhaust cam, but the right hand intake cam is 15-1/2? long, so it’s 1-1/2? shorter than the left hand intake cam that’s 17? long. The ID number for the right intake cam is 100xxxxx and the Chrysler part number is 4792062.

Left hand intake: The left intake cam looks like the right one with both the oblong pad and the chain sprocket, but it’s 17? long and carries a 200xxxxx ID number and a 4792063 Chrysler part number.

Right hand exhaust: The right hand exhaust cam is 15-1/2? long, but it doesn’t have the pad for the cam gear because it’s driven by the chain that’s connected to the intake cam. The right exhaust cam has 300xxxxx etched on it and is available from Chrysler under p/n 4792058.

Left hand exhaust: The left hand exhaust cam looks like the right exhaust cam, but it’s 17? long, just like the left intake cam, and it has 400xxxxx etched on it. It’s listed under p/n 4792059 in the Chrysler parts book.

Front Covers

There have been two front covers used on the 2.7L, depending on where the engine was installed.

• If it’s in one of the LH cars including the Dodge Intrepid or Chrysler Concorde, it came with the 4663614AB/AC front cover that’s flat-faced except for the two raised bolt bosses that are there for the pulleys that are used for the serpentine belt.

• If it’s in one of the JR cars, including the Sebring or Stratus, the front cover has a raised pad that’s located in the middle, toward the top of the cover. The torque axis mount that supports the engine for this transverse installation bolts on to the top of the pad. This cover has 4792604AA cast onto it.

Oil Pans

The 2.7L came with two different aluminum oil pans, too, one for the LH cars and one for the JR cars.

• The oil pan for the LH cars was a 4663743AB casting that sloped up toward the back of the pan. There’s a flat pad on the side of the pan, right behind the oil filter, that was drilled for the return line from the auxiliary oil cooler that was standard on the cars that had the autostick transmission or the police package.

• The pan used on the Sebring and Stratus JR cars was a 4792367AA casting. It had a flat bottom and a scalloped corner toward the back of the pan on the same side as the oil filter. The scallop was needed to make room for the exhaust system on the transverse engines. This pan has a flat pad right behind the oil filter, too, but it was never drilled for any of these applications.

Other Things To Know

That’s about all there is to know about the major components for the 2.7L motor. The castings aren’t all that complicated, but they can throw you a curve if you’re not watching for the differences. However, there are a few more things you should know before building one of these engines.

Rod Bearing Failures

These engines usually fail because they lose a rod bearing, but no one is sure why the rod bearings are failing. Some people think that the coolant from the water pump gets inside the engine if the seal starts leaking, but there are two weep holes that vent to the outside, so that’s probably not the reason for the bearing problems.

A lot of the cores are really sludged-up, so some believe that most of the failures are caused by neglect. However, we know of one car that had the oil changed every 3,000 miles at the dealership and still lost a rod bearing at 60,000 miles, so that’s obviously not the only reason they fail.

Others have suggested that the bearing material that was used for the rod bearings wasn’t right for the application, but no bearing material can stand up to constant abuse, so it probably isn’t fair to blame the bearings themselves for the problem. It may well be that some or all of these factors are contributing to the rod bearing failures, but the bottom line is that no one really knows why they’re failing, so the jury is still out.

However, the service manager at a local Dodge dealer shared an interesting theory that seems to make some sense. He agrees that

neglect will definitely cause the problem, and he’s definitely seen some engines that have been neglected, but he says that even if you use the right oil and change it faithfully, the engine still won’t go the miles because the coolant temperatures are pretty high (the high speed fan comes on at 230º) and the engine only holds four and a half quarts of oil, so the oil gets too hot and it begins to break down.

Multi-viscosity oils revert back to their base viscosity if they’re subjected to too much heat and pressure, so a 5W-20 may well revert back to a 10W or

even a 5W viscosity if it’s “abused,” and that’s just not good enough for these engines.

Running the oil too hot would explain the brown stain we see on the inside of the engines and may even help explain the heavy, thick, greasy sludge that we see on some of the heads. In any case, no matter what causes the bearing failure, it means that about 25 percent of the rods and a lot of the cranks are junk when they come in, so rebuilders should plan on buying plenty of core float.

Computers and Cam Gears

Then there’s the problem with the computers and the cam gears. Chrysler has used two different computers and two different cam gears, depending on the model year and the platform.

• The ’98-’01 Intrepid and Concorde (LH platform) and ’01-’04 Sebring and Stratus (JR platform) used the “current generation engine controller,” so the gear for the left intake cam was p/n 4792305.

• The ’02-’04 Intrepid and Concorde (LH platform) came with the “next generation controller” or “NGC,” so these engines had a different gear for the left intake cam that’s listed as p/n 4792305AB in the Chrysler microfiche. All the windows for the sensor were relocated to correspond to the updated program in the new engine controller, so you must use the cam gear that matches the computer in the car so it can sequence the fuel injection correctly or the car won’t start and run.

• There’s been some confusion over which computer and cam gear were used for the 2.7L engines in the Stratus and Sebring in ’03 and ’04. It seems logical that Chrysler would have switched over to the “next generation computer” in everything in ’03, but that’s not the case according to the parts book. It shows the 4792305 cam gear that goes with the “current generation computer” is still used for the JR cars up through ’04, so apparently Chrysler hasn’t updated this platform yet. It’s probably a good idea to check the cam gear on the core before you sell the engine, just to be sure, though.

Rocker Gaskets

Rebuilders who include gaskets with their engines need to make sure they send the correct rocker cover gaskets. The original gaskets surrounded every bolt hole in the rocker covers, but the later ones only seal on the inside of each hole.

Chrysler supplies this later design as a “fits-all,” but it’s almost impossible to make it work in an early rocker cover. We haven’t been able to determine exactly when Chrysler made the change because of their superseded part numbers, so we include both sets of rocker gaskets with each engine to avoid any problems. It’s cheap insurance.

Harmonic Damper for Cam

The early engines came with a small harmonic damper that was bolted to the front of the right hand cam. Chrysler soon decided it really wasn’t necessary, so they left it off all the later engines. Most rebuilders follow Chrysler’s lead and leave it off all of them.

Oversize Bores

Chrysler says you shouldn’t bore the block oversize and there usually isn’t much wear in the cylinders, so some rebuilders are just honing them .010? oversize, but the sleeves are about .160? thick so it’s safe to bore them .020? oversize and probably even more as long as the pistons and rings are available. Just make sure that the fire rings in the head gaskets don’t hang over the edge of the cylinders after the block is bored and chamfered.

Bent Intake Valves

When the oil pressure drops due to the rod bearing failure, the tensioner backs off and allows the timing chain to go slack. That alters the timing enough to allow the pistons to hit the intake valves. Apparently the exhaust valves “free wheel” when this happens, because we’ve never seen one with a bent exhaust valve.

Oil Pump

Don’t reuse the oil pump without taking it apart and rebuilding it as necessary. Plan on replacing quite a few gears sets and a high percentage of the back covers. The cover has to be flat within .001?, according to the shop manual, or it will allow too much oil to bleed past the back side of the gears and the engine will have low oil pressure. The new cover is available from Chrysler under p/n 4663750.

Water Pump

The water pump is actually inside the engine, so it’s a good idea to buy the best one you can find. Talk to your supplier and make sure you get “the good one.” Some rebuilders are even using the OE Chrysler pump to hedge their bets. It has a reinforced housing and a special bearing that’s supported with nylon to give it more strength and stability.

Cleaning Cylinder Heads

Cleaning the cylinder heads thoroughly can be a challenge because there are lots of holes and passages, including some dead end oil galleries that can trap debris and cause a failure. Plan on spending a lot of time brushing and hand detailing the heads.

Special Cup Plug

Don’t forget to install the special, big cup plug with the small weep hole in it in both heads. It’s available from Chrysler under p/n 4792108.

Tensioner Preload

The tensioner must be filled with oil and fully extended when the engine is fired or the chain will jump a tooth and allow the pistons will hit the intake valves. Make sure the tensioner is fully extended on the test stand and tell the customer to prime the engine thoroughly before starting it or everybody will probably get to do it over again.

Final Thoughts

Chrysler has installed about 200,000 to 250,000 of these engines a year since 1998, so there are well over a million of them out there and most of them are in cars that are worth fixing, especially when the engine fails prematurely. Chrysler’s reman engines are expensive and the junkyards know what the used ones are worth, so there’s a real opportunity for the rebuilder who is ready to build the 2.7L.