Every engine needs some type of intake manifold to route air into the engine’s cylinders.

With carbureted engines, the intake manifold has a wet plenum and runners because the manifold has to flow air and atomized fuel at the same time.

With carbureted engines, the intake manifold has a wet plenum and runners because the manifold has to flow air and atomized fuel at the same time.

Consequently, the manifold runners can’t turn or twist too sharply otherwise the heavier fuel droplets may separate from the air, causing a loss of power.

An intake manifold with a carburetor on a street engine also has to provide a certain amount of heat to help vaporize the fuel when the engine is cold, otherwise cold drivability will suffer.

With multiport fuel injected engines, gasoline direct injection engines and diesel engines, the manifold only has to flow air. One of the advantages of having a dry plenum and runners is that they can twist and turn more sharply to equalize airflow between cylinders without disrupting the air/fuel mixture.

Also, the manifold doesn’t need any heat to keep the fuel vaporized, so a cooler manifold means a denser air charge and more power.

Choosing the “right” intake manifold for an engine is just as important as choosing the right camshaft, cylinder heads and compression ratio. All of these components have to complement one another and work in harmony together otherwise the engine will never realize its true power potential.

Whether you are the one who is choosing the intake manifold or your customer, the choice of what kind of intake manifold to use will depend on a number of things.

Is the manifold going on a stock engine, a street performance engine, an engine that will be used for pulling or towing, a circle track engine, a drag engine, marine engine or what?

If it’s a street engine, does it have to be emissions legal with EGR, PCV and vacuum hookups? If so, the latter will require a CARB-EO number. If it’s a pre-emissions street performance application such as a classic muscle car or street rod, or a racing application, you have a lot more freedom in what you can use.

Power Up

So where do you want the engine to make the most power? That will also affect the type of intake manifold you choose.

Street engines spend 99 percent of their running time between idle and 3,000 rpm. Except for the occasional burst of speed, low end torque and throttle response are much more important than peak horsepower for a street engine.

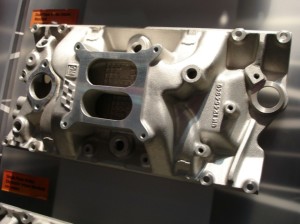

This type of application usually calls for some type of “Dual Plane” (180 degree) intake manifold with a divided plenum.

A “High Rise” manifold that has slightly longer runners and a taller location for the carburetor(s) will usually increase torque and power compared to a “Low Rise” manifold. But you may have to settle for shorter manifold if hood clearance is a problem and your customer doesn’t want to chop a hole in his hood or install a hood scoop to provide extra clearance for the carburetor.

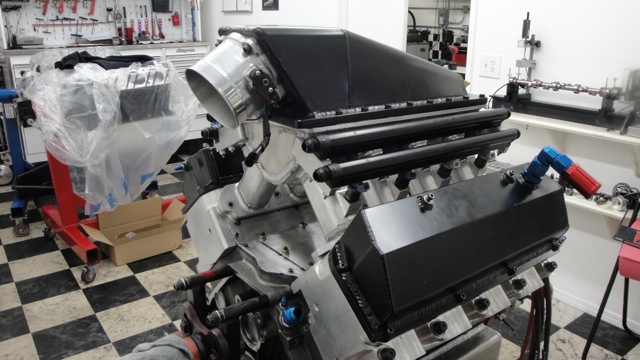

A drag engine, on the other hand, spends most of its time revving hard from 3,500 to 9,500 rpm or higher as it blasts down the quarter mile.

Off idle torque and low end throttle response don’t matter as much as lots of airflow at high rpm – especially if its a large displacement stroker motor that flows a lot of cubic feet per minute (CFM) of air. This type of application usually calls for a Single Plane (360 degree) style intake manifold with a large open plenum and large volume runners.

Single Plane manifolds are typically more for racing than street applications because the usually make the most power in a higher rpm range, say from 2,500 to 7,500 rpm or higher. The typical Dual Plane high rise manifold, by comparison, usually performs best from idle up to about 6,500 rpm.

Some Single Plane manifolds also use an X-configuration for their runners rather than the curved upper/lower style runner layout on a Dual Plane manifold. The X-configuration provides a straighter shot at each port and flows best at higher rpms, say from 3,000 to 8,500 rpm or higher.

Ram Effect

If hood clearance is not an issue, or your customer wants a really aggressive look, the classic “Tunnel Ram” manifold is the ultimate setup for flowing lots of air at higher rpm.

Used mostly for drag racing, a Tunnel Ram style manifold with dual four barrel carburetors has long straight runners that curve slightly as they mate with the cylinder heads.

The long runners give the air a lot of momentum and velocity as it flows towards the intake valves. Ditto for the older “Cross Ram” style manifolds that were used on many Chrysler, Dodge and Plymouth drag engines.

Regardless of its shape or configuration, a well-designed intake manifold should take advantage of something called the “Helmholtz” effect to ram more air into the cylinders with each intake cycle. Intake manifolds, like exhaust manifolds, experience a lot of internal resonance as pressure waves move back and forth inside the runners.

When air rushed toward an open intake valve, it builds up a lot of speed. High air velocity is good because it helps fill the cylinder efficiently for good throttle response, torque and power.

But when the intake valve closes, the air bangs up against the valve and builds up pressure.

This sends a reverse pulse wave back through the air column in the intake runner and plenum, all the way back to the carburetor.

It travels at the speed of sound, so the pressure pulses can reverberate multiple times before the intake valve opens for the next intake stroke.

Multiply this times 8 cylinders and you get a lot of pressure waves bouncing around inside the intake manifold. These pressure pulses can either work for you or against you depending on their magnitude and frequency.

If the length or volume of the intake runners is optimized for a certain rpm range, the Helmholtz effect can actually create a bit of boost pressure just as the intake valve opens, pushing more air into the cylinder for a slight gain in power. Remember – The longer the intake runners, the greater the effect.

That’s why a lot of intake manifolds on late model engines have long, curving runners and/or a variable intake system with flapper valves that effectively change runner length and/or plenum volume.

This allows the manifold to be “tuned” to produce peak airflow (torque/power) within a certain rpm range.

The variable intake manifolds have the advantage of changing runner length and plenum volume for a broader power curve.

They typically use a longer runner length and smaller plenum volume at low rpm for good throttle response and low end torque, then open up the plenum and/or shorten the runner length, or add more runner volume at higher engine speeds to aid top end power.

If you’re building a boosted engine with a turbocharger or centrifugal supercharger, you’ll want a manifold that can handle the extra airflow at higher rpms.

If the engine will be boosted with a roots style supercharger, you’ll need a manifold designed for that type of blower.

Choosing Wisely

Another very important factor that has to be considered when choosing an intake manifold is the type of cylinder heads on the engine. Stock manifolds and stock-replacement manifolds are for stock configuration cylinder heads.

If you are using aftermarket heads that have a different port configuration (different port height, size, location or shape), you’ll need a special manifold that matches the heads and ports.

Many aftermarket cylinder head manufacturers make their own custom intake manifolds that are designed to mate with specific heads they make.

Most of these are racing style manifolds (Single Plane) rather than street manifolds (Dual Plane), and they are often pricier than what you might pay for a “generic” aftermarket performance intake manifold designed for standard heads on a SB/BB Chevy, Ford or Chrysler engine.

For some applications, you might need a custom handmade intake manifold. Nobody may have a manifold that will fit the engine/head combination you are building, or maybe your customer wants something different than what’s available from any supplier. Custom manifolds are made to order based on your specs.

You tell the manifold maker exactly what you want (engine/head application, port location, intake runner length/volume, plenum size/volume and carburetor setup, and they’ll fabricate it. It’s not cheap, but it’s often the only option for one-of-a-kind engines or monster motors that need a lot of air.

Something else to keep in mind when choosing a manifold is that a manifold that is designed for a 283-327-350 SB Chevy may not be the best choice for a stroked 400 to 427 or larger SB Chevy.

The larger the displacement of the engine, the more air it needs and the larger the plenum and runners in the intake manifold have to be. Many aftermarket intake manifold suppliers have higher volume manifolds for the larger stroker motors.

The manifold you choose also has to fit the carburetor(s) or throttle body(s) you want to use on the engine. Most street performance manifolds are machined to accept a standard square base Holley, Carter or Edelbrock carburetor, while many race manifolds are designed for a larger spread bore or Dominator-style carburetor.

Special street manifolds are also available for General Motors Quadrajet carburetors. If a customer is building an open hood vintage style street rod and wants a “Three Duce” (three 2bbl carburetors) setup, there are manifolds to fit three-bolt and four-bolt 2bbl carburetors.

Appearance may also be a consideration.

Cast aluminum is porous and will often stain and discolor over time. An aluminum intake manifold can be painted (clear or silver or any other color), anodized, polished or plated to give it almost any kind of appearance your customer wants. Polishing and plating adds to the cost (up to $200 or more!) but if looks are important it’s worth every penny.

Is Bigger Better?

The plenum in a stock manifold is typically smaller to keep air velocity high. Likewise, the cross-section of the runners is also small to keep the air moving at maximum speed into the cylinder ports.

This provides good idle quality and throttle response, but also limits how much air the manifold can flow at higher engine speeds. Eventually the speed is reached at which the engine will try to pull in more air than the stock intake manifold can flow.

That’s when the stock intake manifold needs to be upgraded to a performance manifold with a larger plenum and larger runners.

Special Features

Some intake manifolds have special features that help keep the runners cooler, such as an air gap or space under the plenum on a SB Chevy to separate the plenum and runners from the lifter valley cover. Keeping the heat of the oil splashing off the cam and lifters away from the intake manifold provides a cooler, denser air charge.

A couple of aftermarket intake manifold suppliers have also developed plastic intake manifolds for older engines such as the SB Chevy. Plastic conducts heat much more slowly than aluminum, so engine heat can’t build up in the manifold and thin out the incoming air.

Plastic is also lightweight, and some of these manifolds feature interchangeable runners that allow you to choose a length/volume that best matches the application.

If you are building an engine that is going to use a power added such as nitrous oxide, you’ll want an intake manifold that has bosses that can be drilled and threaded to accept nitrous oxide spray nozzles.

The manifold should also have bosses or threaded fittings for mounting all applicable engine accessories (support brackets for the alternator, AC compressor, PS pump, etc.). Again, what you need will depend on the application and what kind of belt drive and accessories will be used on the engine.

EFI Issues

If you’re building a late model Ford modular V8 or a Chevy LS and want to convert it to a carburetor for use in an older vehicle or street rod, there are manifolds for that — just as there are EFI manifolds for converting older SB/BB Chevy and Ford engines from a carburetor to fuel injection.

An EFI manifold will be a dry manifold unless it uses a throttle body injection setup.

EFI conversion manifolds usually come as part of a complete EFI system that includes fuel injectors, throttle body and a control computer.

It’s a slick setup that eliminates troublesome automatic chokes and constant fiddling with carburetor jets.

The EFI systems are self-tuning as far as air/fuel mixture adjustments are concerned and use an oxygen sensor in the exhaust to provide a feedback signal to the control module. EFI usually delivers faster starting, better cold drivability and even better fuel economy, which is something to consider for a street performance application.

Manifold Mounting

Installing an intake manifold may be as simple as bolting it in place, or it may require port matching or machining to optimize alignment and fit.

If a manifold is being installed on an engine with stock configuration heads, and the heads have not been ported to change the port size or position in any way, chances are the manifold should line up fairly well. Even so, it’s always a good idea to use the intake manifold gaskets to check alignment between the heads and manifold.

You don’t want and sharp edges or misalignment creating turbulence in the airflow. A die grinder and a little elbow grease may be needed to match the ports for optimum alignment.

Some manifold suppliers recommend leaving a .080˝ gap between the manifold port and the opening in the intake manifold gasket when port matching a manifold to a head.

If you try to grind everything flush so there is no edge between the port and gasket opening, you might remove too much metal from the manifold and ruin it!

With CNC machined heads, the intake manifold may have to be CNC machined or reworked by hand to match the ports. Also, if the heads have been resurfaced (milled), the edges of the manifold where it mates with the block and heads will also have to be machined to compensate for the change in cylinder head height.

If this is not done, it will likely crush the end gaskets under the intake manifold and create misalignment between the intake runners and ports.

Some engine builders like to hand massage as-cast aluminum manifolds to optimize airflow. Removing rough edges and casting seams, and rounding and blending all the corners can usually improve airflow, but like head porting you have to know what you’re doing otherwise you might make things worse.

The basic idea is to eliminate any sharp edges or corners and to avoid creating any sudden changes in runner diameter that might create turbulence. Airflow improvements can be base lined and measured on a flow bench just like a cylinder head to see if the changes you are making are really making any difference.

According to some experts, a slightly rough surface (like medium sandpaper) will actually flow better than a highly polished surface.

A slightly rough surface will form a boundary layer that promotes laminar (parallel) airflow inside the runners. If the surface is too smooth, the air won’t stick to it and small eddy currents will form that create drag and turbulence that reduce airflow.

Another trick some racers use is to treat the underside of an open valley intake manifold with a heat reflective and/or oil shedding coating.

A heat reflective coating will keep the manifold cooler for a denser air charge, and an oil shedding coating will keep hot oil off the underside of the manifold and speed oil return to the crankcase.

When the manifold is mounted on the engine, use sealer around the coolant passage openings in the intake manifold gasket unless it is a composite style gasket with rubber sealing rings or O-rings.

Make sure the mounting surfaces are clean, dry and flat. Tighten the intake manifold bolts to specifications using the correct sequence, which usually means starting with the center bolts and alternating the tightening sequence side to side from the center towards the end.

Over tightening the intake manifold bolts may crush the intake manifold gasket or crack the manifold. Most intake manifold bolts only need 25 ft.-lbs. or less of torque.

After the engine has been started and broken-in, recheck the torque on all of the intake manifold bolts.

If you hear any whistling noises or the engine won’t idle down, you may have an intake vacuum leak. You can use propane or carburetor cleaner to check the seal along the intake manifold gaskets.

If there’s a leak, the propane or carb cleaner will be drawn in through the leak and smooth out the idle. If it’s a late model engine with EFI, computer controls and an OBD II connector, you can use a scan tool to look at fuel trims.

A vacuum leak that’s upsetting the air/fuel mixture will show a lean fuel condition (positive fuel trim correction value) at idle that decreases as engine speed goes up.

An intake vacuum leak will have less of an effect on the air/fuel mixture at higher speeds because there’s more air flowing into the engine through the throttle or carburetor.