We often encounter engines that have a cold-start knock or ticking noise. In this case, the 3.5L V6 engines installed in various Honda models can make a knocking or ticking noise at idle and only when warm.

The cause of the problem is that the rocker shaft bridge has excessive clearance from the factory, which causes the rocker shaft to rotate and make noise. The problem sounds serious, but the fix is very simple – loosen and re-torque the rocker shaft bridge bolts.

Note: Before you adjust the valves, always be sure that the rocker shaft bridge bolts are torqued to the exact specifications and in the sequence outlined in the repair procedure.

Models:

2008-’11 Accord

2010-‘11 Crosstour

2008-’12 Odyssey EX-L/Touring

2009-’12 Pilot

Diagnostic Procedure:

- Start the engine and let it reach normal operating temperature.

- While the engine is idling, listen for a knock or ticking noise. Use a stethoscope to find the location of the noise.

- If you hear knocking or ticking from either cylinder head, go to the Repair Procedure.

• If you hear a noise coming from another location, continue with normal troubleshooting.

Repair Procedure:

- Remove both valve covers.

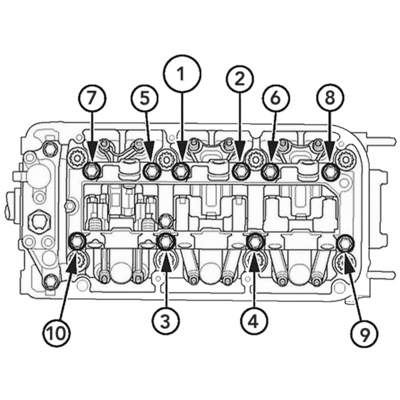

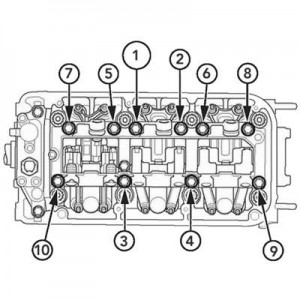

Note: To ease the removal of the valve covers, remove the power steering pump with its hoses connected. This allows access to the wire harness mounting bolts. - On the front cylinder head, loosen and then torque each rocker shaft bridge bolt one at a time in the sequence shown in Fig. 1. Torque the bolts to 21 lb.-ft. (28 Nm) to crush the bridge around the rocker shaft.

Note: The bridge is designed to crush around the rocker shaft so when torquing the bolts, it may initially feel like the bolt is stripped. This is normal. Continue torquing the bolts until the appropriate torque value is reached.

Note:

• Do not replace the bolt, the bridge or the head unless they are damaged.

• To avoid breakage, don’t overtorque the bolts.

• The bridge bolts for VCM and V-TEC engines have the same torque values and tightening sequences. Only the VCM cylinder head is shown in the image.

- On the front cylinder head, loosen and then re-torque each rocker shaft bridge bolt again one at a time in the sequence shown in Fig. 1. Torque the bolts to 18 lb.-ft. (24.5 Nm).

- On the rear cylinder head, loosen and then torque each rocker shaft bridge bolt one at a time in the sequence shown in Fig. 1. Torque the bolts to 21 lb.-ft. (28 Nm) to crush the bridge around the rocker shaft.

- On the rear cylinder head, loosen and then torque each rocker shaft bridge bolt again one at a time in the sequence shown in Fig. 1. Torque the bolts to 18 lb.-ft. (24.5 Nm).

- Check the valve clearances and adjust if needed. Clearance specs: (Cold) Intake: 0.20-0.24 mm (0.008-0.009 in.), Exhaust: 0.28-0.32 mm (0.011-0.013 in.).

- Reinstall the valve covers.

- Reinstall all removed components.

- Start the engine and let it reach normal operating temperature. Verify that the noise is eliminated.

By following this simple procedure, you have not only eliminated a worrisome noise, you’ve given your customer valuable peace of mind knowing that their Honda is now safe and reliable for miles to come.

Written by the ALLDATA® Community Automotive Diagnostic Team, a select group of automotive experts dedicated to helping technicians fix hard-to-repair vehicles more efficiently. Meet the team by visiting . © 2014 ALLDATA LLC.