Engine Builder and Engine Pro present Shop Solutions in each issue of Engine Builder Magazine and at enginebuildermag.com to provide machine shop owners and engine technicians the opportunity to share their knowledge to benefit the entire industry and their own shops. Those who submit Shop Solutions that are published are awarded a prepaid $100 Visa gift card. Submit your Shop Solution at [email protected]. You must include your name, shop name, shop address and shop telephone number. Submitted Shop Solutions not published will be kept on file and reevaluated for each month’s new entries.

DOWEL PIN HOLDER

Dowel pins can cause problems both removing and installing. Once they’ve been removed and the block decked, it’s time to reinstall them. Giant fingers get in the way, so trying to finagle the dowel pin and drive it with a hammer can be cumbersome. I use a boxed end wrench, the size of the dowel, to hold it while I tap it with a hammer to get it started. Then, I take the wrench away to drive it in. I’ve got a cheap wrench I’ve ground to be the approximate thickness of the dowel protrusion.

Big Don Kincaid

Big Don’s Racing Engines

Point, TX

PAIR OF GLASS PLIERS

If you have trouble with flat-band spring-type hose clamps, try using a pair of glass pliers. The jaws are so wide that they hold any hose clamp very securely. They make it easy to compress the clamp for removal, installation, or repositioning. Try it and you will be amazed at how well it works.

David Guarr

Midwest Equipment Specialties

Lenexa, KS

VOLTMETER SPEEDOMETER

For those like me who possess a head and block surfacer that employs a potentiometer to adjust the speed of the traverse, I install a D.C voltmeter on the voltage input of the D.C drive motor. Now, I adjust the finish by the voltage of the motor instead of reading the position of the knob.

Sylvain Tremblay

Les Ateliers de Moteur-Competi-tech, Inc

Ste- Catherine, Quebec, Canada

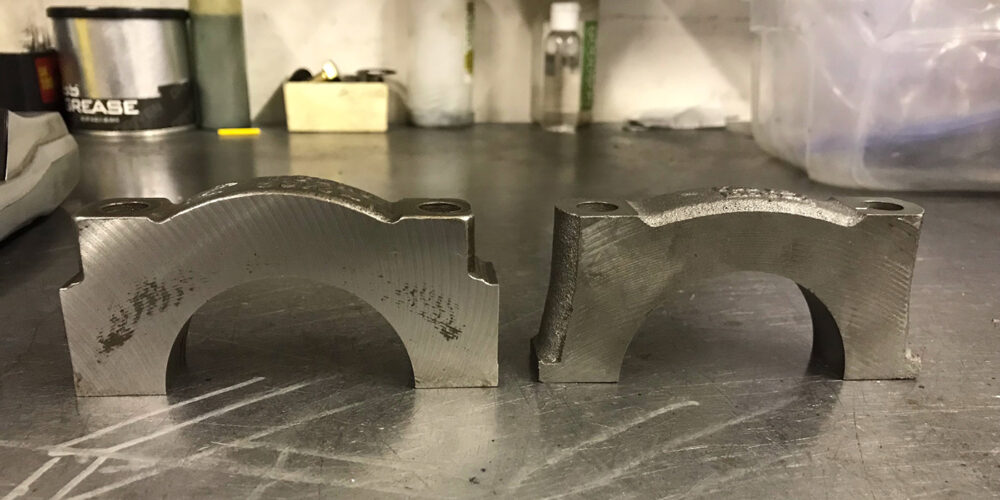

DEDICATED DRIVER

With all the small and big block Chevys we’ve done, I made dedicated cam bearing drivers for removal. This is much quicker than the expandable tools, and if you have only one set it doesn’t have to be cleaned continuously and can be kept for assembly. I counter-bored the bushing drivers to use a 1” bar and keep them in the teardown area.

Randy Torvinen

Torvinen’s Machine

Menahga, MN

MIC CHECK, CHECK

One often overlooked item for regular calibration is the common block deck mic and depth mics. Simply lay it on the corresponding precision blocks on your mill table, or known true surface, and check them once in a while.

Ron Flood

Cedar Machine

North Branch, MN

THE FREE NICKEL TOUR

Often, a new customer will stop by saying, “So-and-so at XYZ Garage told me to stop by and ask for the ‘Free Nickel Tour.’ I’m interested in having a high-performance engine built.” I have found this to be far more productive marketing than answering the same questions over the phone!

One afternoon, I came back from lunch and there’s a young 20-something “new guy,” who I hadn’t met before, refacing some Chevy LS valves. I could tell he was a newbie, as he was moving cautiously and slower than usual. But after watching him do a couple, I could see he was doing an excellent job.

I introduced myself, “Hi, I’m Tom, the company founder and owner, Eric is my son. You must be a new hire. Welcome to our team.”

The guy looked at me a little confused, then said, “No, I just stopped by for the ‘Free Nickel Tour.’ Eric showed me how to reface valves, then let me try a few while he went to check on a block in the CNC machine.” I just patted him on the shoulder and said, “Well son, you’re doing a fine job. Keep it up, you only have 5 more valves to go.”

I wandered across the shop to find Eric, while thinking, “What help shortage? There’s plenty of free help if you know where to find it.”

While you won’t be able to put them all to work, a tour of your facility will go a long way towards creating a bond and trust that their project is in good and expert hands. The attached photo shows some students from Hill College getting a ‘Free Nickel Tour.’

Tom Nichols

Automotive Machine & Supply, Inc

Cleburne, TX