In the dynamic world of automotive engineering, where innovation is the driving force, engine oil remains the unsung hero, silently ensuring the smooth operation and longevity of our vehicles. As technology evolves and consumer demands shift, the landscape of engine oil grades undergoes constant transformation. Understanding these trends is paramount for industry insiders as we delve into the intricate realm of engine oil grades, exploring emerging trends that are shaping the automotive industry.

The automotive sector is no stranger to change. Over the years, we’ve witnessed a significant paradigm shift towards sustainability and efficiency. In response to this, manufacturers are increasingly investing in research and development to create engine oils that not only meet but exceed stringent environmental regulations. Low viscosity oils have emerged as a frontrunner in this regard, offering reduced friction, enhanced fuel efficiency, and lower emissions. This trend towards lighter viscosity grades, such as 0W-20 and 5W-30, reflects a collective commitment towards a greener tomorrow.

Furthermore, the rise of electric and hybrid vehicles has catalyzed a revolution in engine oil formulations. While these vehicles operate on a different paradigm altogether, they still rely on lubricants to optimize performance and ensure component longevity. As a result, we’re witnessing a surge in demand for specialized oils designed specifically for electric and hybrid drivetrains. These formulations prioritize thermal stability and conductivity, effectively managing heat dissipation and protecting vital components in these advanced systems.

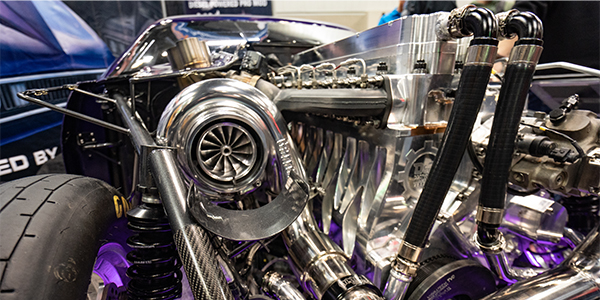

In parallel, the advent of turbocharged engines has redefined the requirements for engine oil grades. Turbochargers operate under extreme conditions, subjecting the oil to higher temperatures and pressures. Consequently, there’s a growing need for oils with superior thermal stability and oxidation resistance. High-performance synthetic oils have become increasingly popular among enthusiasts and professionals alike, offering unmatched protection and performance in turbocharged applications.

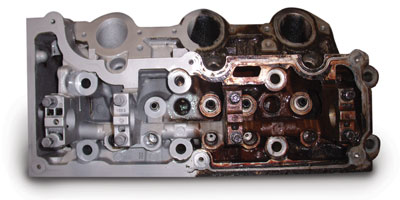

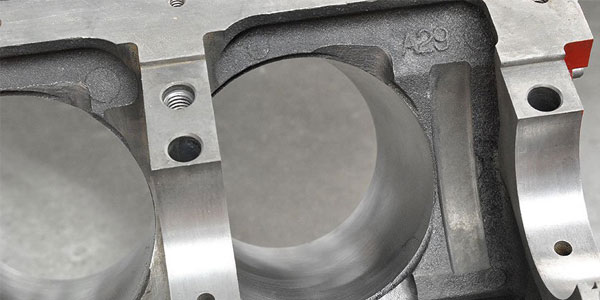

Moreover, the proliferation of direct fuel injection systems has presented unique challenges for engine oil formulations. These systems are prone to carbon buildup and fuel dilution, necessitating oils with advanced detergency and viscosity control properties. As a result, manufacturers are investing heavily in additive technology to combat these issues effectively. Modern engine oils are fortified with detergent and dispersant additives, ensuring optimal engine cleanliness and minimizing wear under demanding operating conditions.

Beyond technological advancements, consumer preferences are also driving trends in engine oil grades. Today’s drivers are more informed and discerning than ever before, demanding products that deliver tangible benefits and value for money. As a result, there’s a growing interest in boutique and specialty oils, tailored to meet the unique requirements of specific vehicle makes and models. From classic cars to high-performance hotrods, enthusiasts are seeking oils that offer uncompromising quality and performance, underscoring the importance of customization in the automotive aftermarket.

In tandem with these developments, the industry is witnessing a shift towards synthetic and semi-synthetic engine oils. While conventional mineral oils once dominated the market, synthetic formulations are quickly gaining traction due to their superior performance and longevity. Synthetic oils offer enhanced thermal stability, improved cold-start performance, and extended drain intervals, making them an attractive proposition for consumers seeking optimal engine protection and efficiency.

As the automotive industry increasingly embraces hybrid technology, the demand for lubricants that meet the unique needs of hybrid engines rises. Polyalphaolefin (PAO) oils, classified as Group IV synthetics, are particularly well-suited for this purpose, outperforming Group III synthetics in several critical areas.

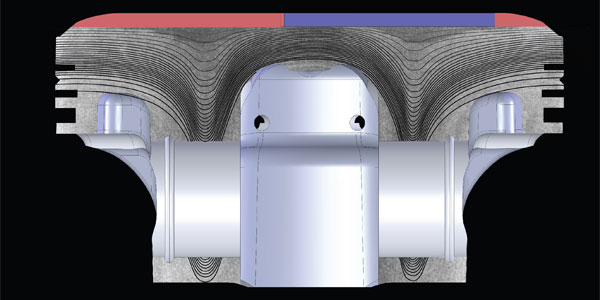

Hybrid vehicles operate in a range of conditions that can challenge traditional oils. PAO oils, with their meticulously engineered molecular structure, provide exceptional thermal stability. This is crucial for hybrids, which frequently shift between electric and combustion engine power, often leading to fluctuating engine temperatures. PAO oils can withstand these temperature variations without breaking down, ensuring consistent lubrication and reducing wear on engine components.

Moreover, the oxidative stability of PAO oils is superior to that of Group III synthetics. Hybrids are designed for efficiency and longevity, and PAO oils contribute to this by resisting oxidation and sludge formation. This means cleaner engines and sustained performance over extended periods, aligning perfectly with the long-term reliability goals of hybrid vehicles.

Low-temperature performance is another area where PAO oils excel. Hybrids often experience start-stop cycles and cold starts, especially in urban environments. PAO oils flow easily at low temperatures, providing immediate protection during these critical moments and preventing engine wear.

Group III synthetics, derived from crude oil and subjected to hydrocracking, still contain impurities and molecular inconsistencies that can limit their performance, particularly under the demanding conditions typical of hybrid and other high-performance engines.

Looking ahead, the future of engine oil grades is poised for further innovation and evolution. As vehicle technologies continue to advance, so too will the demands placed on lubricants. From electric propulsion systems to autonomous vehicles, tomorrow’s engine oils will need to adapt and thrive in an increasingly complex and interconnected automotive ecosystem. As pioneers in the lubricant industry, we remain committed to pushing the boundaries of innovation and delivering solutions that empower drivers to embrace the road ahead with confidence and peace of mind.

Engine oils play a pivotal role in ensuring the longevity and performance of our vehicles. From low viscosity formulations to specialized oils for electric and hybrid drivetrains, the industry is witnessing a wave of innovation driven by technological advancements and consumer preferences. As we navigate this ever-changing landscape, one thing remains clear: the future of engine oil grades is bright, promising, and full of endless possibilities.

Hot Shot’s Secret formulates and manufactures high performance oils. Its Green Diamond Full Synthetic oil is Group III-based and the Blue Diamond line of oils are entirely Group IV PAO-based. Hot Shot’s Secret infuses it’s oils with proprietary FR3 Nano Technology for maximum protection, longevity, and performance gains.

Sponsored by Hot Shot’s Secret.