Engine Builder and Engine Pro present Shop Solutions in each issue of Engine Builder Magazine and at enginebuildermag.com to provide machine shop owners and engine technicians the opportunity to share their knowledge to benefit the entire industry and their own shops. Those who submit Shop Solutions that are published are awarded a prepaid $100 Visa gift card. Submit your Shop Solution at [email protected]. You must include your name, shop name, shop address and shop telephone number. Submitted Shop Solutions not published will be kept on file and reevaluated for each month’s new entries.

LOCK RING GROOVING

Here is a piston spud I made for machining lock ring grooves in pistons on the lathe. It’s the same concept as the ones I make for lifter bushings. This uses the chuck as an end stop so the indicator/DRO setup is the same for both sides – just flip it 180-degrees after machining one side. The I.D. grooving tools and holders are available in many sizes and profiles through tool suppliers.

Ron Flood

Cedar Machine

North Branch, MN

TEAR DOWN CART

I constructed what I call my tear down cart over 30 years ago. It’s 3′ x 5′ with a bend down the middle and a 1″ drop to one side with a drain. I used a plastic 5-gal pail with a Little Giant parts washer pump. The hose comes up through a standoff pipe opposite of the drain. I disassemble heads, strip blocks and if they’re really nasty and dirty I’ll give them a quick scrub to keep the spray washer cleaner longer. It’s great for rinsing off honing oil from rods and pistons.

Randy Torvinen

Torvinen’s Machine Shop

Menahga, MN

INSERT SCREW TIPS

With more insert type tooling being used in the shop, here’s two suggestions to save aggravation when swapping inserts. First, too prevent stripping the socket head on tiny screws holding inserts to the tool, or worse, damaging the tool’s threads, apply a small amount of anti-seize or moly grease on the screw threads. Second, to prevent over-tightening, use the proper, small “winged” wrench to tighten the screw.

Tom Nichols

Automotive Machine

Joshua TX

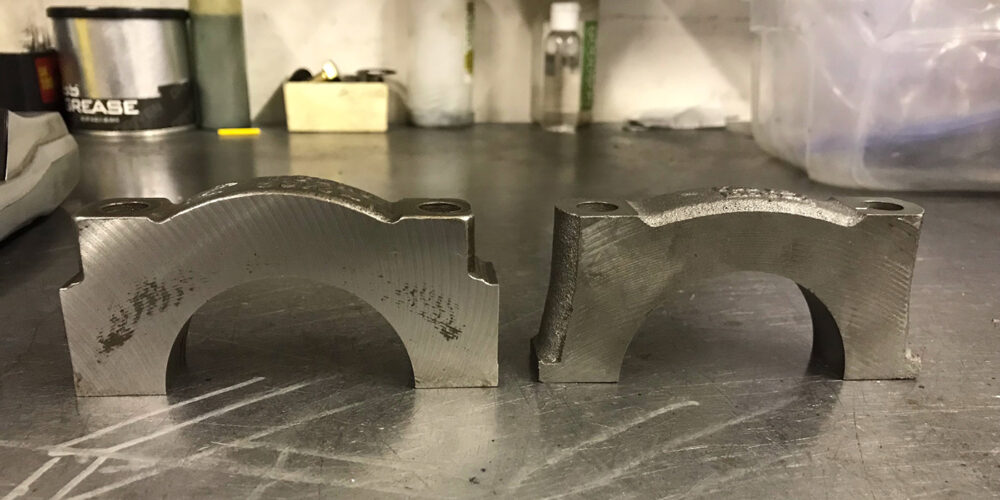

PIN CENTER FIXTURE

This is a fixture I built to locate and center the connecting rod while installing the wrist pin. Simple, but very effective.

Bruce Serene

Hillsboro Race Engines

Hillsboro, KS

SUPER MAGNET

Neodymium magnets are very strong magnets. I attached one to an old valve with epoxy. It makes a good holder for butt facing valve lash caps without fear of losing them.

Tom Prodahl

Cylinder Head Service

Minneapolis, MN

HAND SCRAPED

Scraping bearings and chamfering edges and housing bores is an important task in building an engine. I have several shapes and sizes of lathe tooling cutters that I use by hand. They are precision ground on all four sides for accuracy and a sharp edge. I find that they work better than bearing scrapers for some tasks.

Dave Matton

D and D Auto Machine

Bloomington, MN